Pupa 1000

Automatic bag making machine for the production of shoppers and large shopping bags from plastic films.

Pupa 1000 is a new welding machine for the production of bottom-seal open-mouth bags, shoppers and large shopping bags from tubular films.

PE tubular film materials include: HDPE or LDPE.

Versatility, reliability, welding quality and simplicity of use are the main features of this bag machine machine.

Pupa is equipped with special SHOPPER SEALING BARS in the central area of the welding machine, for the production of double seal bag stacks.

The bag stacks are placed on the collection belt, ready to be punched to obtain shoppers or large shopping bags. (The cutting die can be supplied separately).

This machine is especially suitable for printed materials; side gusseting can be performed on request, as part of the processing cycle.

By excluding the shopper sealing function, the machine can be used for the production of “open mouth” sacks and bags confirming its versatility characteristic.

Changes in length and thickness do not lead to production downtime.

All functions of the welding machine are programmed via a terminal with a large display for entering production parameters and displaying diagnostic messages.

The Pupa 1000 welding machine is completely protected by a transparent makralon cover that guarantees total safety of the operators while allowing continuous control of production.

The machine conforms to standards

Customization at the service

of your business.

The software program for all the welding machines and the accessories has been developed entirely within the company by specialized engineers.

The machine control programs can be personalized according to the customer’s production requirements.

- The load-bearing structure is stabilized and made of noble metals.

- Roll holder complete with shafts and braking system.

- Roller conveyor with special reinforced profiles.

- Welding unit fitted with nickel/chromium convex sealing strips and electronic heat control to obtain homogeneous and resistant welding.

- Autofocus photocell for printed material.

- Brushless servomotor to ensure constant control of the material infeed speed in sync with the welding bar.

- Feed rollers and gusseting units protected by a patented anti-rolling system.

- Automatic, continuous cycle bag bundles collection belt for NON-STOP production.

| Open mouth bag min/max length | 100 – 3000 mm |

| Open mouth bag maximum width | 1000 mm |

| Shopper min/max length | 200 – 1300 mm |

| Shopper maximum width | 900 mm |

| Weldable thickness with open mouth sealing bars | min 2 x 10 microns – max 2 x 200 microns |

| Weldable thickness with shopper sealing bars | min 2 x 30 microns – max 2 x 200 microns |

| Min/max cadence | 15/160 c/min |

| Max film unwinding speed | 100 m/min |

| Power supply | 400 V three-phase + G + N Hz 50 |

| Max absorbed power | 8,5 kW |

| Air consumption | 350 l/min 8/9 bar |

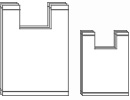

Bottom seal sack

Bottom seal, side gusset sack

Double seal bag stacks

Shopper bag (cutting die can be supplied separately)

Open bottom double seal sack (handle punch can be supplied separately)